PIMS (Production Information Management System) is also called "Shop Floor System" or "Factory Information System", which is versatile software tool for electronics production control and management.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes.

Ascentest developed PIMS Production Information Management System for production management and control of electronics products, based on years of experience on Electronics Test & Measurement and Production.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes.

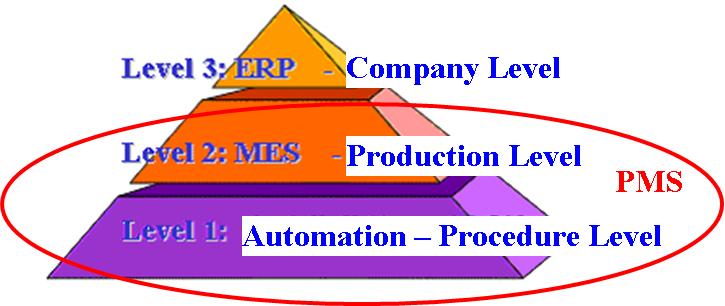

PIMS is similar with ERP (Enterprise Resource Planning) and MRP (Manufacturing Resource Planning) in some ways. But ERP/MRP are more focused on company operation, while PMS is more focused on production daily management.

According to the 3-Layer Model proposed by AMR(Advanced Manufacturing Research Institute of USA) in 1992 for enterprise information system integration, PMS covers Level 1 (Production Automation) & a part of Level 2 (MES, Manufacturing Execution System).

Just like ERP/MRP/MES, the implementation of PIMS needs support from company’s high level management team, to setup project team and coordinate the inter-department cooperation. |