|

|

|

|

|

|

|

|

|

|

| Related products |

ACTP Test System Software Platform

ACTP (Ascentest Test System Software Platform) is software platform for automatic test system development & management, test sequence execution, data collection and analysis.

ACTP is ideal software platform for developing small and middle scale systems of test automation, which provides numerous practical functions and application interfaces for convenient secondary development and easier system operation, by implementing modular & object oriented programing techniques.

ACTP is now mature, stable and code-efficient System Software Platform after continuous improvement and successful implementation in different test system applications for different customers. ACTP Test System Software Platform

ACTP (Ascentest Test System Software Platform) is software platform for automatic test system development & management, test sequence execution, data collection and analysis.

ACTP is ideal software platform for developing small and middle scale systems of test automation, which provides numerous practical functions and application interfaces for convenient secondary development and easier system operation, by implementing modular & object oriented programing techniques.

ACTP is now mature, stable and code-efficient System Software Platform after continuous improvement and successful implementation in different test system applications for different customers. PIMS Production Information Management System

PIMS (Production Information Management System) is also called "Shop Floor System" or "Factory Information System", which is versatile software tool for electronics production control and management.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes. PIMS Production Information Management System

PIMS (Production Information Management System) is also called "Shop Floor System" or "Factory Information System", which is versatile software tool for electronics production control and management.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes. MPS-Tester-SW Multi-port Vector Network Analysis System Software

MPS-Tester-SW System Software controls Ascentest MPS Multi-Port RF/Microwave Switch Matrix and Vector Network Analyzer, to make accurate and fast S-Parameter measurement on multi-port components, such as 4-port Directional Couplers and 9-port Smart Antennas, as well Smart Phone Multi-band Antennas.

The software can also be used to control Vector Network Analyzer to measure S-Parameter directly and automatically. MPS-Tester-SW Multi-port Vector Network Analysis System Software

MPS-Tester-SW System Software controls Ascentest MPS Multi-Port RF/Microwave Switch Matrix and Vector Network Analyzer, to make accurate and fast S-Parameter measurement on multi-port components, such as 4-port Directional Couplers and 9-port Smart Antennas, as well Smart Phone Multi-band Antennas.

The software can also be used to control Vector Network Analyzer to measure S-Parameter directly and automatically. |

| |

| Product features and technical data: |

| System overview |

PIMS (Production Information Management System) is also called "Shop Floor System" or "Factory Information System", which is versatile software tool for electronics production control and management.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes.

Ascentest developed PIMS Production Information Management System for production management and control of electronics products, based on years of experience on Electronics Test & Measurement and Production.

PIMS collects the data from the key work stations, and then stores, sorts, analyzes all the collected data and generates results and reports to help manage production procedures, improve production efficiency, reduce production cost and avoid mistakes.

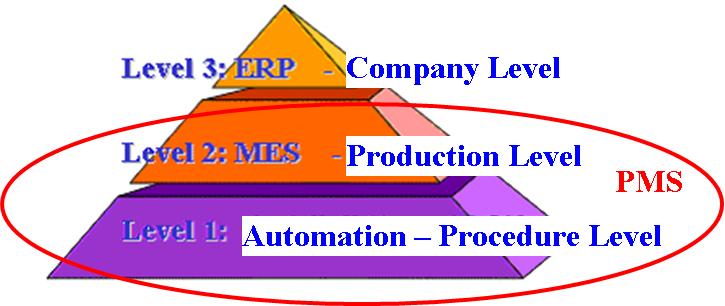

PIMS is similar with ERP (Enterprise Resource Planning) and MRP (Manufacturing Resource Planning) in some ways. But ERP/MRP are more focused on company operation, while PMS is more focused on production daily management.

According to the 3-Layer Model proposed by AMR(Advanced Manufacturing Research Institute of USA) in 1992 for enterprise information system integration, PMS covers Level 1 (Production Automation) & a part of Level 2 (MES, Manufacturing Execution System).

Just like ERP/MRP/MES, the implementation of PIMS needs support from company’s high level management team, to setup project team and coordinate the inter-department cooperation. |

| Function characteristics |

PIMS Basic Functions:

1. Work Order management

2. Product Model Management

3. Serial number/bar code management

4. Process flow control

5. Operator Management

6. Key equipment management

7. Key resource management, like IMEI

8. Test data management and analysis

9. Repair history information management

10. Direct functional station support, like SB card, Packing, etc.

11. Monitoring, Analyzing & Reporting Functions

PMS Featured Functions:

1. Pre-built frameworks for many functional stations required in a product line, with good SOP consideration. Can easily be customized for different product models.

2. Flexible line configuration definition to fit for different manufacturing mode/different product requirement.

3. Full coverage on each single UUT throughout the whole process.

4. Easy interfacing with test system for test data collection, with rich data analysis functions

5. Real time data processing, almost no delay. Paper free operation possible

6. Optional “Data Digging” service for in-depth analysis on collected data to provide statistical basis for optimizing production procedures, balancing productivities of procedures, speeding up model change, dynamically allocation of equipment & human resources, fast trouble shooting of product defects,analysis on component failures, and evaluation of operator’s skill levels.

7. PMS can be upgrade to a complete MES system by integrating more functions of production control, QC,reports, etc.

PMS Management & Analysis Tools:

1. SPC Monitor (Statistical Process Control)

* Process Yield

* Station Yield

* Work Progress

* Section Report

* IMEI Report

2. Result Analysis

* Pass Fail Analysis

* Distribution Analysis

* Trend Analysis

* Test Time statistic

3. Report Tools

* Work Report

* Monthly Report

* Weekly Report

* Daily Report

* Model Report

* Repair Report

* Station Report

* etc. |

| |

|

| |

| Software structure |

|

| Order information( Contact us) |

| PIMS Production Information Management System |

| |

|

|

|